Back when I began pipe smoking in the early 1970’s, thought that smoking pipes had two parts; the bowl/shank, and the stem. Most days I still think of a pipe that way. But then, I’m the kind of guy who tries to keep everything as simple as possible. Too much thinking makes me either get a headache or fall asleep. But, a couple of years ago during the pandemic, I learned a valuable lesson or two about the intricacies of what all goes into creating a handsome smoking pipe that also smokes as good as it looks.

A group of pipe makers a couple of years back, asked me to be a guest at one of their monthly Zoom video meetings. So, I joined the group and had a lot of fun chatting with them about aged tobaccos, which is the only reason they invited me. I sure couldn’t speak with a lick of authority regarding pipe making. I’m a guy who would have trouble carving a toothpick in half if you gave me a sharp knife. And as I have already confessed, I’m also a guy who always thought of a pipe as having two parts, the wooden part and the plastic part. You stuff tobacco into the bowl of the wood part and you stick the plastic part in your mouth to light and smoke the darned thing. Well, I sure got a lesson on how wrong I was! So now, after being educated, I thought I would share my knowledge with you – ha!

A group of pipe makers a couple of years back, asked me to be a guest at one of their monthly Zoom video meetings. So, I joined the group and had a lot of fun chatting with them about aged tobaccos, which is the only reason they invited me. I sure couldn’t speak with a lick of authority regarding pipe making. I’m a guy who would have trouble carving a toothpick in half if you gave me a sharp knife. And as I have already confessed, I’m also a guy who always thought of a pipe as having two parts, the wooden part and the plastic part. You stuff tobacco into the bowl of the wood part and you stick the plastic part in your mouth to light and smoke the darned thing. Well, I sure got a lesson on how wrong I was! So now, after being educated, I thought I would share my knowledge with you – ha!

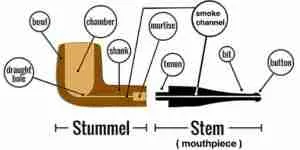

To enjoy your pipe, you need to have a well cured bowl that is well drilled internally down through the shank into the plastic part, which I’ll from now on refer to as the stem. At the butt of the shank there has to be a widened area called a mortise that is finely polished to accept the tenon (the part of the stem that goes into the mortise). The stem/mortise area has to have a perfect fit and made to handle extensive wear as the removal and reinsertion process takes place literally hundreds of times over the course of the life of the pipe. I listened as the pipe makers spoke of an untold number of ways to get a perfect tenon to mortise fit. In fact, I nearly fell asleep at one point while they excitedly talked about it (please don’t tell them I said that).

To enjoy your pipe, you need to have a well cured bowl that is well drilled internally down through the shank into the plastic part, which I’ll from now on refer to as the stem. At the butt of the shank there has to be a widened area called a mortise that is finely polished to accept the tenon (the part of the stem that goes into the mortise). The stem/mortise area has to have a perfect fit and made to handle extensive wear as the removal and reinsertion process takes place literally hundreds of times over the course of the life of the pipe. I listened as the pipe makers spoke of an untold number of ways to get a perfect tenon to mortise fit. In fact, I nearly fell asleep at one point while they excitedly talked about it (please don’t tell them I said that).

One of the most over looked and most important features of a pipe is the lip area of the stem. It must be thin for comfort, yet sturdy enough to withstand a little scratching, biting, chewing, etc. The maker of a pipe must work very carefully with whatever stem material he is working with (plastic, vulcanite, horn, amber, etc.), to ensure that the lip area meets the comfort criteria. Who wants a fat lip on their pipes? Not me!

One of the most over looked and most important features of a pipe is the lip area of the stem. It must be thin for comfort, yet sturdy enough to withstand a little scratching, biting, chewing, etc. The maker of a pipe must work very carefully with whatever stem material he is working with (plastic, vulcanite, horn, amber, etc.), to ensure that the lip area meets the comfort criteria. Who wants a fat lip on their pipes? Not me!

The “slot” of the stem (I always called it a button), is also extremely important. You want the clefts to be tall enough to be held by the front teeth on occasion, yet slim enough to be comfortable. I am told that a good slot is one that has just enough buildup at the top and bottom of the slot (highly polished for additional comfort), and just wide enough to disperse the heated air so as not to cause the smoker to get that nasty old tongue bite!

The “slot” of the stem (I always called it a button), is also extremely important. You want the clefts to be tall enough to be held by the front teeth on occasion, yet slim enough to be comfortable. I am told that a good slot is one that has just enough buildup at the top and bottom of the slot (highly polished for additional comfort), and just wide enough to disperse the heated air so as not to cause the smoker to get that nasty old tongue bite!

Another thing that the pipe makers discussed that had them excited was the best way to get their pipes to really shine brightly once the creation process is over. They want their pipes to make the best presentation possible in order to get a sale. There were all kinds of discussions about various buffing and polishing equipment and how to best get their pipes polished up nicely. I suggested a nice Buster Brown shoe polishing brush but that was met with incredulity for the most part.

Another thing that the pipe makers discussed that had them excited was the best way to get their pipes to really shine brightly once the creation process is over. They want their pipes to make the best presentation possible in order to get a sale. There were all kinds of discussions about various buffing and polishing equipment and how to best get their pipes polished up nicely. I suggested a nice Buster Brown shoe polishing brush but that was met with incredulity for the most part.

There did seem to be a consensus that using a buffing wheel and something called Carnuaba wax was the best way to polish a pipe. It comes in liquid form, broken up chunks or solid bricks. I learned that Carnuaba wax comes from a type of Palm tree called Copernicia Prunifera. I couldn’t pronounce Copernicia Prunifera, so it must be good stuff. I was told it polishes hard wood extremely well and doesn’t melt nearly as fast as waxes that have a lower melting point. And, it is vegetable grade and even used in the food industry, particularly to coat hard candies to keep them from melting. So, if you are one of those people who likes to lick your pipe bowls before smoking, you should be okay and not get poisoned. Good to know as I’ve always been a little concerned about that.

There did seem to be a consensus that using a buffing wheel and something called Carnuaba wax was the best way to polish a pipe. It comes in liquid form, broken up chunks or solid bricks. I learned that Carnuaba wax comes from a type of Palm tree called Copernicia Prunifera. I couldn’t pronounce Copernicia Prunifera, so it must be good stuff. I was told it polishes hard wood extremely well and doesn’t melt nearly as fast as waxes that have a lower melting point. And, it is vegetable grade and even used in the food industry, particularly to coat hard candies to keep them from melting. So, if you are one of those people who likes to lick your pipe bowls before smoking, you should be okay and not get poisoned. Good to know as I’ve always been a little concerned about that.

The next time you are on the hunt for a fine hand made smoking pipe, such as this Jody Davis Ramses style piece that I’m displaying here, you will now be full of knowledge about what it takes to make a pipe worthy of that wonderful old aged tobacco that you are smoking (purchased from my website, of course). And for the record, this blog barely scratched the surface of what it takes for the world’s pipe artisans to produce a handsome hand made smoking pipe. I’ve been in the business for a lot of years, and never cease to be amazed at the long hours of hard work that is put into the making of a wonderful smoking implement for people like you and me. And here I always thought that a pipe was simple a piece of wood attached to a piece of plastic with a hole running through the middle. Shame on me!

The next time you are on the hunt for a fine hand made smoking pipe, such as this Jody Davis Ramses style piece that I’m displaying here, you will now be full of knowledge about what it takes to make a pipe worthy of that wonderful old aged tobacco that you are smoking (purchased from my website, of course). And for the record, this blog barely scratched the surface of what it takes for the world’s pipe artisans to produce a handsome hand made smoking pipe. I’ve been in the business for a lot of years, and never cease to be amazed at the long hours of hard work that is put into the making of a wonderful smoking implement for people like you and me. And here I always thought that a pipe was simple a piece of wood attached to a piece of plastic with a hole running through the middle. Shame on me!

Happy Puffing,

Steve